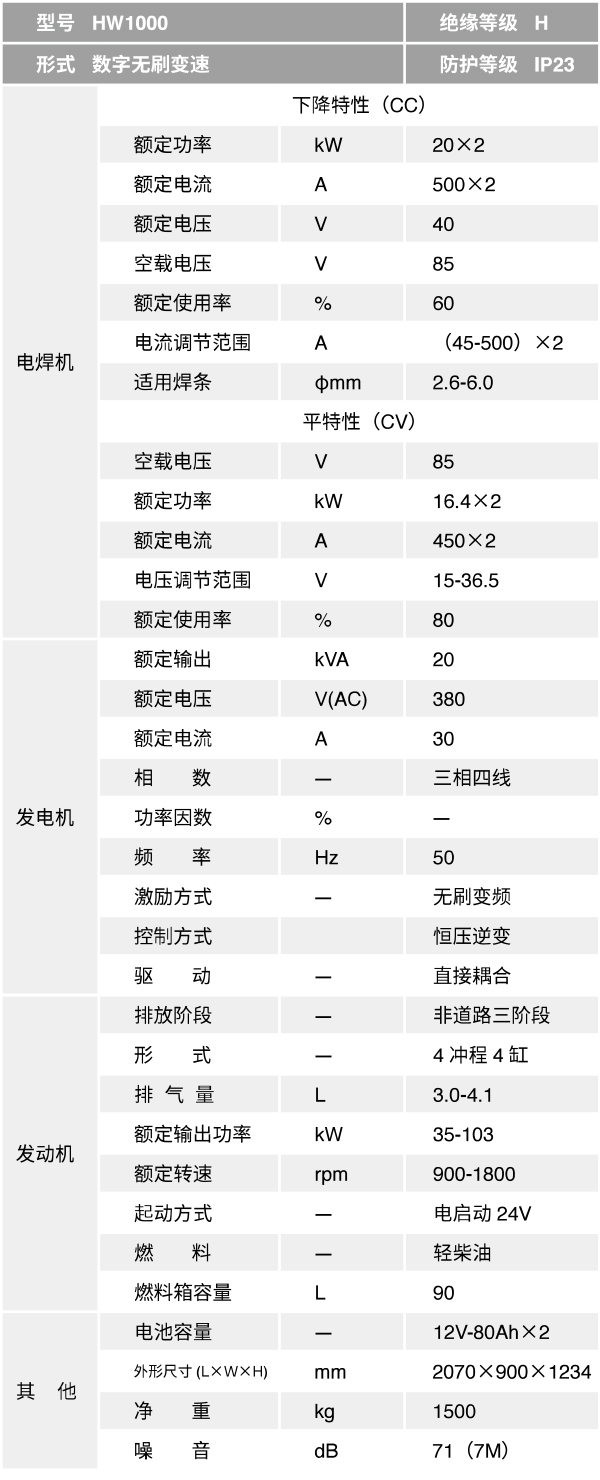

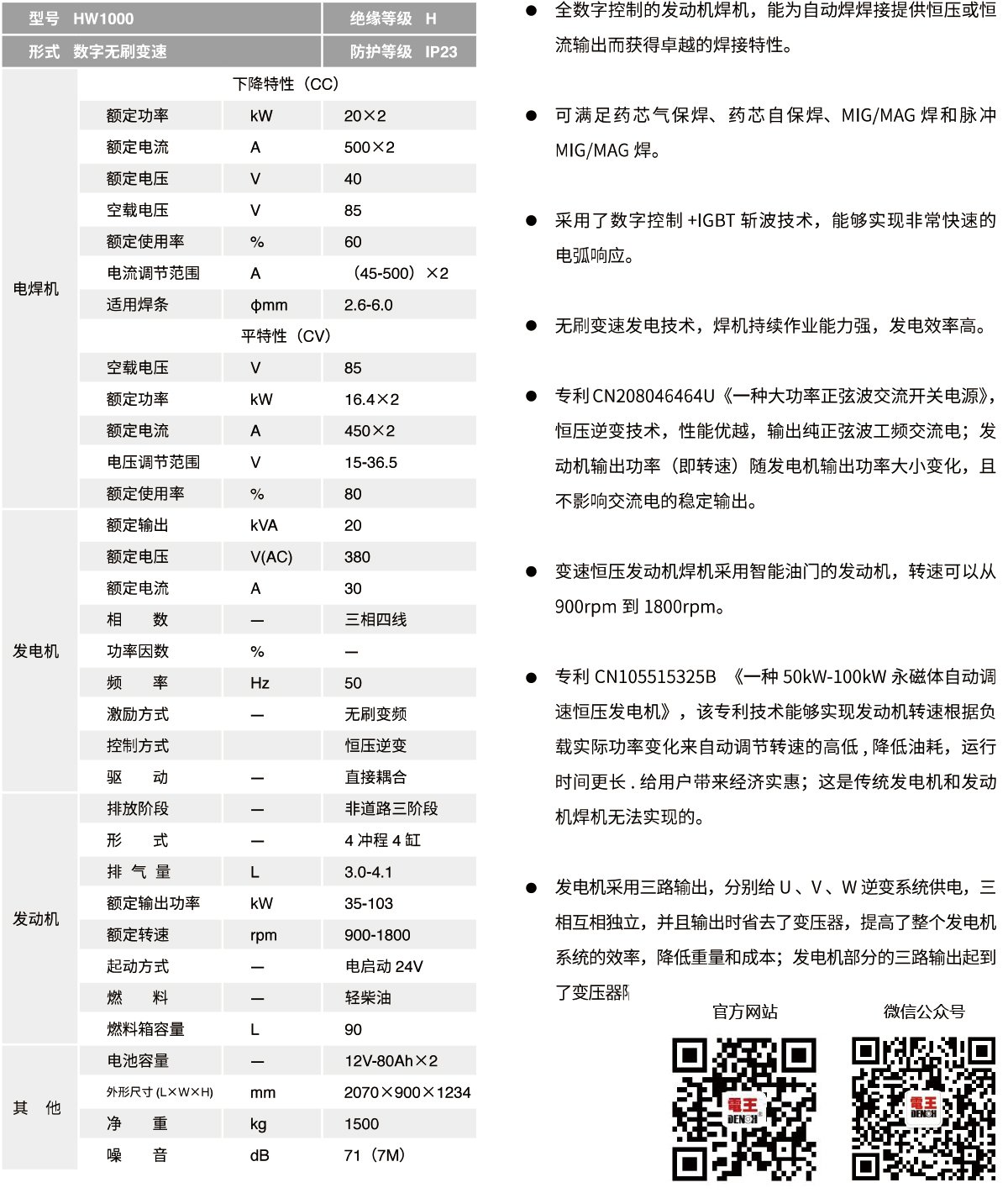

技术先进性:

- 无刷诱导子发电技术

- IGBT斩波控制技术,IGBT斩波焊机逆变频率高,HW1000可达35kHz。因此变压器体积小,整机重量轻,方便移动;IGBT控制及主电路较为简单,所以可靠性高,故障点少,易于维修。

- 全桥逆变降压与任功耗开关Buck(新波)复合新型拓扑结构,弧长和焊接热输入双闭环控制系统,突破传统“线能量”控制的局限,实现从“线能量”到“点能量控制的转变。焊接相比其他类型逆变焊机更稳定。

- 可同时带2套自动单枪外焊焊接设备,同时满足一套45kW中频加热系统使用

- 采用DFJ(低飞溅)波形控制技术,飞溅小、焊接熔池稳定,焊接一致性好。

- 可满足药芯气保焊、MIG/MAG焊和脉冲MIG/MAG焊。

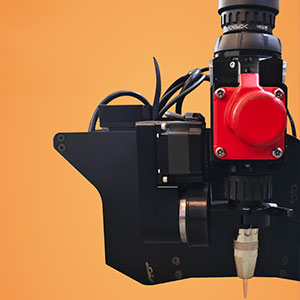

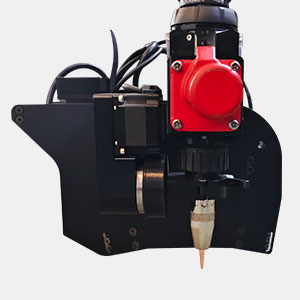

- 总之,该机器发电效率高,持续作业能力强,且重量轻,方便移动,适应性及适用范围广,可用于手把焊,半自动焊和全自动焊接机器人。适合野外焊接作业。已经广泛应用于城市建设,桥梁焊接,管道工程,救灾抢险等各领域.

- Progressiveness technology:

Brushless inducer power generation technology

IGBT chopping control technology, IGBT chopping welding machine has a high inverter frequency, HW1000 could achieve 35kHz. Therefore, the transformer has a small volume, light weight, and is easy to move; The IGBT control and main circuit are relatively simple, so they have high reliability, fewer fault points, and are easy to maintain.

A new topology structure combining full bridge inverter voltage reduction and any power consumption switch Buck (new wave), with a dual closed-loop control system for arc length and welding heat input, breaks through the limitations of traditional “line energy” control and realizes the transition from “line energy” to “point energy control. Welding is more stable compared with other types of inverter welding machines.

It can be equipped with two sets of automatic single gun external welding equipment at the same time, and can also meet the use of a 45kW intermediate frequency heating system

Using DFJ (Low Splash) waveform control technology, the spatter is small, the welding pool is stable, and the welding consistency is good.

Can meet the requirements of gas shielded welding, MIG/MAG welding, and pulse MIG/MAG welding.

In summary, this machine has high power generation efficiency, strong continuous operation ability, light weight, convenient movement, wide adaptability and applicability, and can be used for manual welding, semi-automatic welding, and fully automatic welding robots. Suitable for field welding operations. It has been widely used in various fields such as urban construction, bridge welding, pipeline engineering, disaster relief and rescue